If I were to say: “Hi are how you? Brent I’m Hull.” You might wonder what I drank for breakfast. I mean, you’d recognize the words, they’d sound familiar, but the way I used them wouldn’t make any sense. But if I said: “Hi, how are you? I’m Brent Hull,” you’d respond without a hitch, my words would make perfect sense (depending on what you drank for breakfast!).

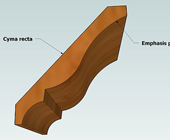

Well guess what? There is a language to classical design, too; a vocabulary that’s dependent on moldings for communicating purpose in a room. If you speak the language, all your finish work—your, bookcases, mantelpieces, doorways, and ceilings―will communicate fluently with your customers. Read the full article…